Solving the Challenges of Packaging with Trays

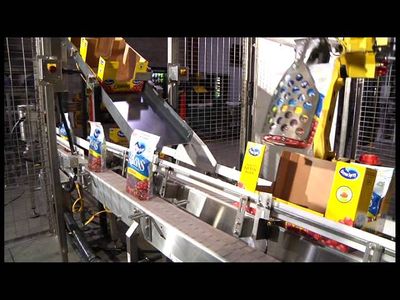

In today's fast-paced production world, efficiency in packing products into trays and then palletizing them is crucial to the success of any business that requires products to be effectively displayed while remaining contained. A good example of this can be found in any big box store, including Sam's Club, Costco, and BJ's Wholesale Club. However, packaging with trays for storage and distribution comes with a unique set of challenges. This is true particularly when the packing and palletizing process involves trays of different sizes, shapes, and content types. Understanding the obstacles that must be overcome is the key to optimizing packaging systems and ensuring goods reach their destination without damage.

For information on the differences between packaging with trays vs. cases, click here.

The Challenges

- Varied Tray Sizes and Shapes: Trays can come in an assortment of dimensions and configurations, requiring a versatile packaging system that can adapt on the fly.

- High-Speed Production Lines: Production demands often call for rapid processing of trays, which must be packed and palletized with unerring accuracy as quickly as possible.

- Delicate and Irregular Products: Items that are fragile or unconventionally shaped need extra care during the packing process to avoid any potential damage.

- Effective Stacking and Space Utilization: The arrangement of trays on a pallet is critical for a display that is appealing while also maximizing space and maintaining stability during transit.

- Automation and Workforce Concerns: With the push towards automation, there's a need to enhance worker safety, lower labor costs, and increase the production output.

The Solution

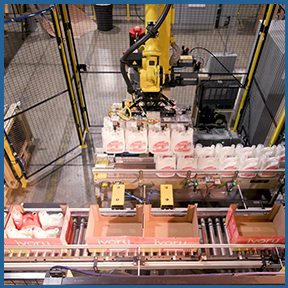

Kaufman Engineered Systems stands at the forefront of designing, building, and implementing automated systems that address these challenges. Our solutions are tailored to each customer's unique requirements - they are as innovative as they are effective at resolving the challenges listed above:

- Adaptable Packing and Palletizing: Our advanced solutions are designed to accommodate whatever tray sizes and shapes need to be packaged, swiftly adjusting to your product specifications without the need for time-consuming changeovers.

- High-Speed Precision: Engineered with high-velocity operations in mind, our systems ensure that even the fastest production line maintains precision, with nominal and surge rates built-in to avoid any slow-downs or mishandling.

- Handling with Care: Through specialized tooling and sensors, Kaufman's technology is sensitive enough to efficiently handle products that are delicate or awkwardly shaped, making sure that the integrity of each item is preserved from packing to palletizing or depalletizing.

- Smart Stacking Technologies: We've optimized the way trays are stacked, focusing on stability and spatial efficiency to prevent damage and maintain product quality all the way to your customers.

- Automation That Elevates: Our systems emphasize automation not only to improve safety and reduce labor costs but to enhance overall productivity, propelling your business forward in today's competitive markets.

Videos for Automated Systems Working with Trays