The Power of Automation: Benefits of Robotic Labelers for Packaging

Packaging is an essential cog in the manufacturing process. It not only safeguards the product but also enhances its appeal to customers. In today's fast-paced world, automation has become a game-changer in this domain. Robotic labelers are just one more aspect of automation that has revolutionized packaging processes by offering a slew of benefits that range from improved efficiency and cost-effectiveness to quality and flexibility. Read on and watch the videos to learn all about the advantages of robotic labelers as well as what to consider when looking for a solution that will work for your company.

Contact us today for information on what Kaufman Engineered Systems can do for you!

Robotic Labeler Videos

KEY BENEFITS OF ROBOTIC LABELERS:

Boosting Productivity and Speed - One of the prime advantages of robotic labeling systems is their ability to significantly increase productivity. Unlike manual processes, robots can work around the clock without fatigue or loss of precision, which translates to higher output. Furthermore, these machines are incredibly fast, capable of applying labels at a pace that far outstrips human capabilities.

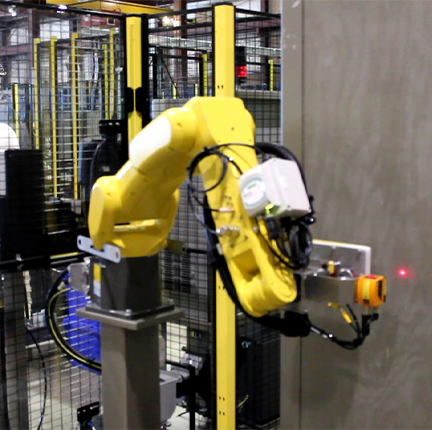

While high speeds are an advantage in some cases, it's important to note that safety is an important factor. If the system will need to be out in the open within close proximity to employees, a collaborative robotic labeler would be the best option. These labelers are designed to work alongside humans in shared spaces. They may not be as fast as other types of labelers, but when the system is not contained behind a safety fence or frequent interaction with humans is required, collaborative robotic labelers are the way to go.

Ensuring Quality and Error Prevention - Robotic labelers are famed for their accuracy and consistency. They ensure that each label is placed precisely where it needs to be every single time. This consistency is crucial in maintaining brand image and product quality. Moreover, the automation of labeling reduces the likelihood of errors that can occur in manual processes, thereby minimizing waste and rework.

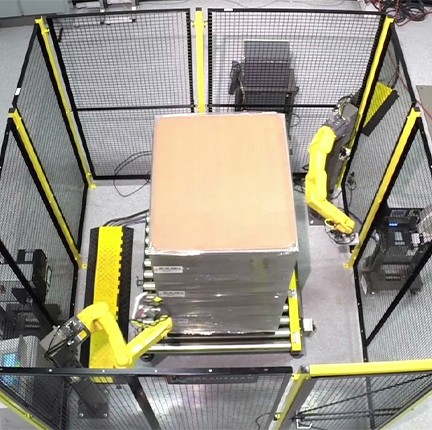

Offering Flexibility and Adaptability - The adaptability of robotic labelers is another compelling benefit. These machines can cater to a wide array of products, sizes, and shapes, making them versatile across different industries. Additionally, they can swiftly adjust to changes in product lines or packaging designs, ensuring that businesses can respond promptly to market trends.

Reducing Labor Costs and Enhancing Safety - Automated labeling systems can substantially reduce labor costs. By taking over repetitive and monotonous tasks, they free up employees to focus on more critical and value-adding work. Moreover, these robots improve workplace safety by performing tasks that could be potentially hazardous for humans.

Sustainability and Waste Reduction - Robotic labelers can also contribute to sustainability efforts. By improving accuracy and reducing errors, these machines cut down on waste, leading to more efficient use of resources.

In Conclusion - The integration of robotic labelers into packaging processes offers immense benefits. As technology continues to advance, these systems will undoubtedly become even more efficient, adaptable, and integral to the packaging industry.

KEY FEATURES TO LOOK FOR IN AUTOMATED LABELING SOLUTIONS:

As we mentioned at the beginning of this article, automation is transforming the packaging industry, and robotic labelers are at the forefront of this revolution. But with the plethora of options available, how do you choose the right solution for your unique needs? In this section, we'll outline key features to look for when investing in a robotic labeling system.

Speed and Efficiency - One of the primary reasons businesses turn to automation is to improve productivity. Therefore, the speed at which a robotic labeler can apply labels is a crucial consideration. High-speed labeling systems can significantly enhance throughput and reduce bottlenecks in the production line.

Again, when the system is out in the open in close proximity to personnel or when frequent interaction with humans is required, collaborative models are crucial to ensuring the safety of your people.

Precision and Accuracy - Accuracy in label placement is vital for maintaining product quality and brand image. Look for a robotic labeler that guarantees precision, ensuring every label is placed exactly where it needs to be - every single time.

Flexibility and Adaptability - The best robotic labelers are those that can handle a wide variety of products, sizes, and shapes. They should be able to adjust to changes in product lines or packaging designs swiftly. The ability to accommodate different label materials and adhesives is also an essential feature to consider.

User-Friendly Interface - A robotic labeler should be easy to operate and maintain. A user-friendly interface that allows for simple programming and troubleshooting can save time and reduce the learning curve for your employees.

Durability and Reliability - Given that these machines will likely be operating around the clock, durability is a must. A robust, well-built machine that can withstand continuous use without frequent breakdowns is a worthy investment.

Integration Capabilities - Your new robotic labeler needs to fit seamlessly into your existing production line. Ensure that the system you choose can integrate with your current machinery and software systems.

Safety Features - Safety is paramount in any automated process. Look for robotic labelers with built-in safety features like emergency stop buttons, light curtains, or safety scanners that can detect human presence and prevent accidents.

After-Sales Support - Finally, good after-sales support is critical. Whether it's installation, maintenance, or addressing unexpected issues, having reliable support from the manufacturer can make all the difference.

In Conclusion - Selecting a robotic labeler involves careful consideration of several factors. By focusing on these key features, you can ensure that you invest in a solution that meets your specific needs and delivers optimal performance.