Configurable Automation to Future-Proof Your Packaging Line

Packaging Today, Unknowns Tomorrow

Customer expectations change. SKUs multiply. Retailer requirements are tightened. Labor gets harder to find. Through it all, your packaging line has to keep running — and keep up.

That’s where configurable automation comes in. Instead of building a rigid system that’s perfect only for today, Kaufman Engineered Systems (KES) helps you design modular, scalable solutions that can flex with your business five, ten, or even fifteen years down the road.

This page breaks down what “configurable” really means, how modularity and scalability protect your investment, and what to consider when planning an automation project built for the future.

Request a Quote ---- Contact Us ---- JOIN OUR MAILING LIST

What Is Configurable Automation?

Configurable automation is more than “custom equipment.” It’s an approach to system design where:

- Core building blocks are modular – conveyors, infeed systems, case packers, palletizers, stretch wrappers, and peripherals are designed as interoperable modules.

- Software and controls are flexible – recipes, SKUs, layer patterns, and routing logic can be changed without re-engineering the whole system.

- Mechanical design anticipates change – structure, clearances, and safety guarding are planned with future stations, lanes, or equipment in mind.

At Kaufman Engineered Systems, that often looks like:

- Palletizing cells that can accept additional SKUs, patterns, and end-of-arm tools without heavy rework.

- System layouts that allow you to add a second robot, infeed lane, or stretch wrapper as volumes grow.

- Controls strategies that make it easy to add devices and functions while keeping a unified HMI experience for operators.

In short: configurable automation turns your packaging line into a platform you can evolve, not a fixed asset you outgrow.

Why Modularity and Scalability Matter

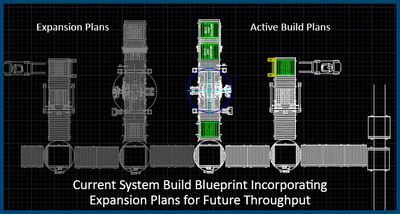

Blueprint for initial system installation with plans for expansion in the future.

1. Product Mix Is Only Getting More Complex - Shorter product lifecycles, more flavors, seasonal packs, and multi-pack promotions all strain traditional, single-purpose systems. Configurable automation lets you:

- Build standard modules (case erect, pack, seal, palletize, wrap) that can be rearranged or expanded.

- Efficiently introduce new SKUs and pallet patterns through software changes, not new hardware.

- Run multiple formats on the same line, with minimal changeover time.

2. Labor and Space Are Too Valuable to Waste - Most plants can’t simply “add another line.” Configurable, modular systems help you:

- Get more throughput from the footprint you already have.

- Design cells that can be reconfigured or expanded in stages as demand grows.

- Make better use of your workforce by moving people from repetitive tasks to higher-value roles.

3. ROI Is Measured Over Years, Not Months - A system that’s perfect today but obsolete in 3–5 years is a costly mistake. Configurable automation helps protect ROI by:

- Reducing the need for major rebuilds when products or volumes change.

- Extending the useful life of your equipment through upgrades, not replacements.

- Supporting phased investments — you can start with what you need now and add on when the business case is clear.

Key Design Considerations for Configurable Automation

Automated EOAT Changeover

System designed with a robot that automatically detaches from one EOAT and connects to another to seamlessly switch between tasks or product size/type.

When Kaufman Engineered Systems partners with a customer on a future-ready packaging line, we look far beyond the immediate project scope. Here are some of the core considerations we evaluate together.

1. Current and Future Product Portfolio

Questions to consider:

- What SKUs are running today — and what’s coming in the next 6 months to a year?

- Will you introduce new case sizes, pack patterns, or bundle types?

- Are there retailer-specific requirements (labels, mixed pallets, slip sheets, top caps) that might expand?

How KES responds:

- We can design in range, not just a single target: case size windows, weight ranges, and pattern flexibility.

- We are able to plan for tooling flexibility at the robot and case-handling level, so new product introductions are smoother.

- We can build in recipe-driven control so operators can quickly select or adjust patterns for new customers.

2. Throughput and Growth Roadmap

Questions to consider:

- What is your required throughput today?

- How much growth do you anticipate in 1, 3, and 5 years?

- Are there peak seasons where you may need temporary extra capacity?

How KES responds:

- We model line capacity to determine the best initial configuration.

- We identify “expansion joints” in the layout: places where an additional palletizer, infeed, or wrapper can be added without a full redesign.

- We may recommend starting with a single-robot cell that can later be mirrored or expanded into a dual-robot configuration as volume grows.

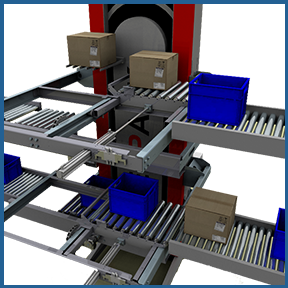

Space saving multi-level conveyance options.

3. Facility Constraints and Floor Space

Questions to consider:

- Are there low ceilings, columns, or traffic aisles that constrain layout?

- Do you expect to reconfigure adjacent processes or add equipment near this line in the future?

- Are there dock-door or warehouse constraints that influence pallet flow?

How KES responds:

- We design compact, modular cells that respect your existing constraints but leave clear paths for expansion.

- We may recommend stackable or multi-level conveyance, or re-orienting product flow to unlock future options.

- We use real-world system modeling to test “what-if” layouts before any steel is ordered.

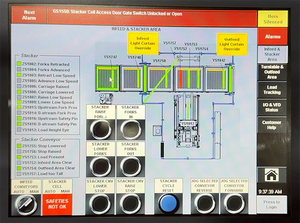

4. Controls Architecture and Data Strategy - Configurable, scalable automation depends on a flexible controls and data foundation.

Questions to consider:

- How integrated is your plant-wide controls and SCADA environment?

- Do you have (or want) OEE, downtime tracking, and production reporting linked to the packaging line?

- Will you need the system to tie into ERP, WMS, or MES in the future?

How KES responds:

- We design controls architectures that support modular expansion — adding devices, robots, and I/O without ripping out core controls.

- We ensure the HMI strategy remains consistent and intuitive even as new modules come online.

- We can provide data visibility and connectivity options that match your current level of digital maturity but allow for growth.

Example of one our HMI touchscreen controls. This one is contained within the HMI set up for one of our dual load stackers.

5. Changeover, Uptime, and Maintainability

Even the most flexible system must be practical for operators and maintenance teams.

Questions to consider:

- How often will you change SKUs, formats, or pallet patterns?

- What is your in-house comfort level with robotics, PLCs, and HMIs?

- Do you have 24/7 coverage or limited maintenance resources?

How KES responds:

- We design recipe-based changeovers and touchscreen controls that maximize efficiency and reduce manual labor.

- We plan for easy access to wear parts, belts, and tooling, and we standardize components where possible.

- We offer training and documentation tailored to your team, empowering them to support and adapt the system over the long term.

Practical Steps to Maximize ROI with Configurable Automation

When you’re evaluating automation partners and solutions, use these practical steps to ensure you’re investing in a truly future-ready system:

- Define a 5–7 Year Vision, Not Just a 12-Month Need

- Document anticipated product changes, growth targets, and new customers you’re pursuing.

- Share this roadmap with Kaufman Engineered Systems (KES) so the design will anticipate where you’re going, not just where you are.

- Insist on Modular Building Blocks

- Ask how easily new modules can be added — extra infeeds, pallet positions, robots, wrappers, labelers, etc.

- Clarify whether expanding the system will require major structural changes or just plugging in additional modules.

- Evaluate Software Flexibility as Carefully as Hardware

- Request demonstrations of SKU / recipe management, pattern editing, and diagnostic tools.

- Ensure your team can add or modify patterns without calling a programmer for every change.

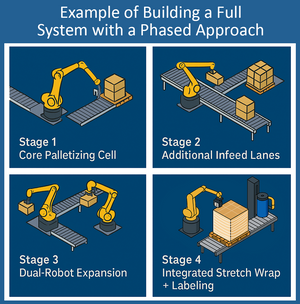

- Plan a Phased Implementation Strategy

- Start with a core system that solves your most pressing bottlenecks.

- Build a roadmap with KES for Stage 2 and Stage 3 expansions — with budgetary estimates and timeline ranges.

- Quantify Total Cost of Ownership (TCO), Not Just Purchase Price

- Consider expected downtime reduction, labor reallocation, and scrap reduction.

- Factor in the cost of future changeovers and upgrades — configurable systems should reduce these costs.

How Kaufman Engineered Systems Helps You Future-Proof

Kaufman Engineered Systems brings decades of experience designing and integrating end-of-line and packaging automation across a wide range of industries. What sets us apart when it comes to configurable, future-ready systems:

- Consultative approach – We invest time up front to understand your products, processes, people, and long-term goals, not just your spec sheet.

- Deep mechanical and controls expertise – Our mechanical and electrical/controls engineers work side-by-side to design systems that are both physically modular and controls-flexible.

- Simulation and proof-of-concept – We use system modeling and simulation to validate cycle times, product flows, and expansion scenarios before equipment is built.

- Lifecycle partnership – From initial design to commissioning, training, and future expansions, we stay engaged as your needs evolve.

When you partner with KES, you’re not just buying a machine — you’re investing in a configurable automation platform engineered to grow with your business.

Is Your Packaging Line Ready for What's Next?

Is Your Packaging Line Ready for What’s Next? If your operation is feeling the strain of new SKUs, higher volumes, or retailer demands, now is the time to explore configurable automation.

Kaufman Engineered Systems can help you:

- Identify where modular automation will generate the greatest ROI.

- Design a solution that fits your footprint today and can expand tomorrow.

- Build a packaging line that’s ready for whatever your market demands next.

Ready to future-proof your packaging line?

Connect with Kaufman Engineered Systems to discuss a configurable automation strategy tailored to your facility, your products, and your growth plans.

We’ll help you turn today’s automation investment into a flexible, scalable foundation for the future.

Request a Quote ---- Contact Us ---- JOIN OUR MAILING LIST