FANUC Robotic and Material Handling Case Studies

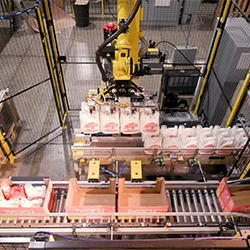

Robotic Depalletizing System with Cooling Vein Removal and Re-palletizing

Check out the video and details for this recently completed system, which utilizes a FANUC M-410iB/700 robot to depalletize loads while removing and stacking cooling veins for re-use and then re-palletizing the loads correctly. A process that was previously manual, making it time-consuming and labor-intensive, caused safety issues and impeded throughput. Find out how Kaufman helped yet another customer implement an automation system to improve their operations!

See Automation Come to Life - In Just Minutes

Watch as a full-scale robotic automation system featuring numerous FANUC robots and components comes together in record time! Our latest time-lapse video captures the precision, scale, and expertise behind a large system build by Kaufman Engineered Systems. If you've ever wondered what goes into creating a world-class automation solution--this is your chance to see it in action.

Utilizing the R&D Lab and Engineers for a Custom Robotics System

A filter manufacturer came to us to see if we could design and build a completely custom solution to successfully automate the case packing process for large volumes of delicate filters at high speeds and with precision to prevent product damage. We engaged our Research and development Engineers, who utilized our R&D lab to develop and build a reliable and consistent solution to meet their throughput and productivity requirements in a high-speed environment.

KPal V Palletizer System: Four Separate Lines Converge for End-of-Line Completion

Check out the video and description for this recently completed system consisting of four product lines with independent palletizer cells fitted with four FANUC M-410i C / 185 robots and four independent stretch wrapping cells utilizing Kaufman turntable stretch wrappers. The entire system then employs the use of one transfer car that moves finished unit loads to the material handling line for robotic labeling that ensures loads are correctly double-stacked at the end of the line.

KPal V Full Layer Bulk Palletizing System for Glass Bottles

Our customer needed a new system to quickly and efficiently palletize glass bottles while meeting clear-cut requirements for performance and delivery schedule. Kaufman designed and built the system with two FANUC 410i B 140H robots with end-of-arm tools tailored to make one sweep rows of bottles into palletization format and the other move and place dunnage as needed. In addition, the system utilizes a FANUC 410i C 500H robot with an end-of-arm tool specifically designed to palletize the bottles. Find out how Kaufman designed and built this system to meet the customer's specific needs!

Robotic Palletizing System for Multiple Lines

Our customer requested a system to fully automate four product lines within the limited space they had available while ensuring that fork truck traffic would not be impeded. The system also needed to ensure the stability of the loaded pallets from start to finish. This system was built with four FANUC M-410ic/185 robots, a transfer car built in-house, and our KForce R20 stretch wrapper. Find out how Kaufman designed and built this system to meet the customer's needs!

Robotic Bag Palletizing System with Weight Checker/Bag Reject Functionality

This system was built with a FANUC 410iB 140H robot and the end-of-arm tool Kaufman designed specifically for bags. The customer requirements for this project included the need for the system to withstand a highly corrosive environment and operate efficiently and accurately at high speeds to accommodate their palletizing rate specifications. Find out how Kaufman designed and built this system to meet the customer's needs!

Robotic Case Packing and Clamp Palletizing System with Stretch Wrapper

This system was built with FANUC robots and Kaufman's KPac case packing, KPal clamp palletizing, and KForce stretch wrapping capabilities. The system was built for automated end-of-line packaging of plastic containers and was designed and built to meet the customer's specific needs.

KPal V Case Palletizing System with KForce R20 Corner Board Stretch Wrapper

Searching for a complete Robotic Palletizing and Corner Board Stretch Wrapping System? Kaufman has your solution! We've built a KPal V robotic case palletizing system complete with an automatic Kaufman KForce R20c corner board stretch wrapper.

Robotic Tote Palletizing System

Kaufman Engineered Systems KPal V palletizing system utilizes two FANUC 410iB/185H robots with high-speed vacuum end-of-arm tools capable of building 6 orders at a time.

High Speed Bag Palletizing System

Kaufman Engineered Systems' automatic palletizing system utilizes a FANUC 410iB/140H robot with a high-speed end-of-arm tool that is capable of palletizing 22+ bags per minute.

Tote and Case Robotic Palletizer with Qimarox Elevators

Kaufman Engineered Systems' automatic end-of-line case and tote palletizing system utilizes a FANUC M-410iC/185 robot which picks tier sheets, totes, and cases. The integrated Qimarox elevators transport the totes to be filled in the manufacturing process and then lowered to the cell to be palletized for transport. The Qimarox elevators are a small footprint alternative to traditional spirals.

Small Footprint Case Palletizing System With Fenceless Loading Zone

When limited floor space is an issue, The Kaufman Engineered Systems KPal Compact Palletizer is a perfect fit.

Equipped to pick and place pallets and tier sheets which are easily accessible for reloading in the fenceless loading zone with the protection of a Keyence Safety Laser Scanner.

KRLV1 Collaborative Robotic Labeler with Vision Verification

Kaufman Engineered Systems' automatic end-of-line labeling system utilizes a FANUC CR-7iA/L Collaborative robot which can easily be added to existing palletizing and stretch wrapping lines.

With the use of FANUC iR vision, the label is scanned to verify placement and correct position. The label presence verification scan assures that the barcode is present and can be read if needed for data transfer to WMS or other unit operations.

High Speed Picking, Packing and Palletizing System for Trays and Cases

A custom robotic system from Kaufman Engineered Systems utilizes a FANUC M-2iA Series Delta robot to orient cans with the assistance of FANUC iR vision and line tracking to be packed into cases and trays.

A FANUC R-1000iA Series robot packs 8, 12, and 24 count cases which are automatically sealed and conveyed to the palletizing cell. A completed palletized load is labeled and verified by a Kaufman Engineered Systems KRL1V Robotic labeler which uses a FANUC LRMate 200iD/7L. After the labeling process, A Kaufman model SXPA-20 automatic stretch wrapper secures the load for shipment.

K6 Full-Tier Case and Open Tray Palletizer

Utilizing two FANUC 710iB/50H robots for tier formation, palletizing with a FANUC 410iB/450 robot (with the new K6 full-tier palletizing end-of-arm-tooling), and using a 410ib/140H FANUC robot (with IR vision) to pick tier sheets, slip sheets, and pallets.

Dual Robotic Case Palletizing System

Two FANUC 410ib-140 series robots with customized vacuum end-of-arm tooling case palletizing a single unit load utilizing space check.

Full Layer Depalletizing and Palletizing System

Kaufman Engineered Systems KDPal K5P robotic depalletizer, including a Kaufman KPalS robotic palletizer and Kaufman model Expa-15 automatic stretch wrap system.

Kaufman’s Bulk PET Bottle Palletizing System

Kaufman Engineered Systems' full-layer, K5 bulk PET plastic bottle palletizing system features three FANUC robots, a multilane infeed conveyor, and dynamic dunnage.

Kaufman’s Robotic Stack and Wrap Palletizing System

Kaufman Engineered Systems’ stack and wrap palletizing system has the versatility of 3 separate palletizing modes.

Case Palletizing and KForce Corner Board Stretch Wrapper

Kaufman’s exclusively designed palletizing system robotically picks and palletizes cases using the custom-designed spatula end-of-arm tooling. A gantry-style sheet dispenser automatically places a top sheet on the fully palletized load before entering the stretch wrapping cell.

Kaufman Engineered Systems is a premier integrator for FANUC robotics offering robotic palletizing, depalletizing, case packing, high-speed picking, and labeling. In addition, Kaufman manufacturers their own line of stretch wrapping, pallet conveying, pallet stacking, pallet dispensing, and other material handling offerings. Couple all this with in-house controls and Kaufman has the complete solution. Let us help you create your next end-of-line solution.