End-of-Line Automation Articles

Future Proof Your Packaging Line with Scalable Automation

In today’s fast-changing manufacturing landscape, a one-and-done automation system can quickly become a bottleneck. On the Configurable Automation page, we unpack how a modular, scalable design helps you build packaging solutions that evolve with your business — accommodating more SKUs, changing throughput demands, and future growth without costly rebuilds. Learn how Kaufman Engineered Systems leverages flexible modules, adaptable controls, and thoughtful design planning to turn your automation investment into a platform you won’t outgrow. Click through to explore how configurable automation protects ROI and keeps your line ready for whatever comes next.

Maximize Throughput Without Sacrificing Space

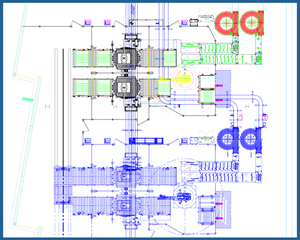

Struggling to grow productivity in a facility where every square foot counts? On the Small Footprint Automation page, we share smart automation strategies designed specifically for space-constrained manufacturing environments. Discover how compact robotic cells, vertical conveyance, modular layouts, and simulation-driven planning can boost pallets per hour and improve safety — all without expanding your footprint. Backed by Kaufman Engineered Systems’ decades of experience and digital modeling tools such as Emulate3D and RoboGuide, this guide shows how to solve tight-layout challenges with precision automation that fits. Click through to learn how space-efficient design can unlock big gains for your packaging line.

Kickstart Your Automation Strategy with Confidence

Curious about how to begin your automation transformation the right way? In “Start Your Automation Journey,” we break down the critical early decisions that growing manufacturers face when adopting industrial automation — from identifying high-impact processes to prioritizing scalable investments that deliver real results. Backed by decades of hands-on experience and advanced simulation tools, Kaufman Engineered Systems guides you through a proven, step-by-step approach to launching an automation project that boosts efficiency, minimizes risk, and sets the foundation for long-term growth. Ready to learn where to start and how to make your first automation project a success? Dive in and discover practical insights for smart automation planning.

5 Signs It's Time to Upgrade

Feeling the strain of aging palletizing equipment that's slowing you down or driving up costs? Kaufman Engineered Systems shows you how to spot the tell-tale signs: frequent breakdowns, wonky load stacking, bottlenecks in throughput, safety gaps, and rising operating costs. Discover how their modern robotic palletizing solutions deliver faster, safer, and more reliable performance—transforming your operation and future-proofing your bottom line. Dive in to learn the 5 Signs It’s Time to Upgrade Your Palletizing System and see how the right upgrade can pay off.

Utilizing Simulations to Build a Better Solutions from the Start

Discover how Kaufman Engineered Systems brings automation concepts to life before they're ever built. This article reveals how powerful simulation tools like Rockwell's Emulate3D and FANUC's RoboGuide allow our experts to visualize, test, and optimize automation systems in a virtual environment—saving time, reducing risk, and ensuring peak performance. Click below to see how virtual simulation turns complex ideas into proven, high-efficiency solutions.

Discover What's Next in Robotic Automation for the Supply Chain

As automation technology evolves, manufacturers and distribution centers must stay ahead of the curve. In our latest article, we explore the most impactful trends in robotic automation—covering everything from vision-guided systems and smart controls to advanced material handling and conveyor integration. See how Kaufman Engineered Systems is delivering the future of automation today.

Control & Software Options

In this article, we are focusing on the various controllers and software options to consider when integrating FANUC robots into your automation solutions for manufacturing, warehousing, and distribution facilities. Every FANUC robot comes with an SOP controller, but there are additional control and software options you need to decide on in order to make the robot palletize or depalletize loads in optimum layouts, integrate safety protocols that allow for a smaller footprint, and allow communication between all the components. This article walks you through the various options and describes how they work together for a robotic system that delivers the desired results.

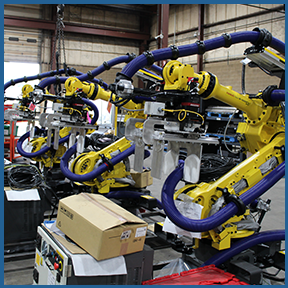

FANUC Level 5 Authorized System Integrator

Kaufman Engineered Systems has a long-standing, exclusive partnership with FANUC America, the world's leading provider of automation technologies, to bring cutting-edge robotic solutions to our customers. This alliance leverages FANUC's comprehensive range of industrial and collaborative robots alongside Kaufman's nearly 30 years in partnership with FANUC and 75+ years of expertise in designing, building, and installing automated systems. Integrating FANUC robots into our systems ensures that we deliver superior end-of-line automation and material handling solutions to our customers.

Key Cost Considerations for Robotic Palletizer Systems

Have you ever wondered how the cost of an automated robotic packaging/palletizing system is determined? This article focuses on all the variables that need to be taken into consideration in order to accurately estimate the cost of any system we design, build, and install for our customers. Each system must meet the unique requirements of the customer, increasing productivity and throughput, lowering costs, and improving safety. This article provides in-depth information that will help you understand the costs associated with our systems.

Everything You Need to Know About Conveyor Solutions

This article provides an in-depth review of the applications of conveyor solutions within robotic automation systems. It provides a general overview of how they impact systems built to automate industrial material handling with robots and lists some of the types of conveyor solutions commonly used. Each listed type links to more detailed information on that particular conveyor type, including applications within industrial manufacturing and distribution automation systems.

End-of-Arm Tooling (EOAT) Solutions: Critical for Robotic Automation

Find out why our in-depth knowledge and experience in designing and building custom end-of-arm tools for every robot is pivotal to the success of our systems. Our extensive skills with in-house EOAT design and manufacturing take the risk out of procuring and implementing new automation systems because we've done this kind of work for countless projects over so many decades. We understand the longevity of the parts on each end-of-arm tool; we have the knowledge to interface the tools to the robots with Ethernet. Kaufman Engineered Systems can easily design a tool for your specific pallets and sheets. Find out about the various standard types of end effectors we've designed, as well as the custom work we've been doing for over 40 years.

Trays vs. Cases for Packaging Products

In the packaging industry, trays and cases are designed with distinct purposes in mind, catering to the diverse requirements of products ranging from food items to fragile electronics. This article aims to shed light on the differences between packaging products in trays versus cases. By delving into the benefits and limitations of each, we will explore how businesses are making informed decisions that not only safeguard their products but also elevate their brand in the eyes of the consumer.

Partner with KES to Increase Efficiency & Innovation!

We invite you to watch another exclusive video compilation showcasing the best of our automated end-of-line robotic systems from last year. Witness firsthand how our advanced technology can streamline your own operations, increase productivity, and drive profitability. Whether you have one facility or one hundred facilities, Kaufman can partner with you to improve your business in 2024.

Don't get left behind in the fast-paced world of manufacturing and distribution. Discover how KES can enhance your operations and give you a competitive edge in the coming year.

Large Roll Handling & Mandrel Extraction

Handling large rolls and performing mandrel extraction can be a challenging task, especially in industrial settings. The sheer size and weight of these rolls can make manual handling not only difficult but also potentially hazardous. Workers may be at risk of injury due to the physical strain or accidents that can occur during the handling process. Additionally, manual handling often requires more time and effort, which can lower overall productivity.

Mandrel extraction is another complex task that involves removing the core around which the roll material is wound. This procedure requires precision and care to prevent damage to the roll or the mandrel itself. Manual extraction can be tedious, and there's always a risk of human error, leading to costly mistakes.

Click below to find out how automated solutions are revolutionizing these processes.

The Art of Club Packaging: What You Need to Know

In the context of big box stores such as Sam's Club, Costco, and BJ's Wholesale Club, club packaging involves physical design and a strategic approach to ensure the product stands out on the floor and the shelves. This could mean more extensive packaging that offers additional room for graphics, text, and creative marketing ideas. Get guidance and tips for creating club packs that move products and increase your bottom line.

The Benefits of Robotic Labelers for Packaging

Packaging is an essential cog in the manufacturing process. It not only safeguards the product but also enhances its appeal to customers. In today's fast-paced world, automation has become a game changer in this domain. Robotic labelers, in particular, have revolutionized packaging processes by offering a slew of benefits that range from improved efficiency and cost-effectiveness to quality and flexibility.

In this article, we cover the benefits of robotic labelers as well as key features to consider when looking for an automated labeling solution. We also showcase videos of some of our own systems in action.

Everything You Need to Know About Automated Stretch Wrappers

Automated stretch wrappers are an essential part of modern packaging operations, but there’s a lot to know about them in order to choose the right solutions for your specific requirements. This article provides an overview of automated stretch wrappers and explores the benefits they offer businesses in terms of efficiency, cost savings, product quality, and safety. It examines the various types of systems available as well as the applications they are suited for. Finally, it explores the various options to consider in a system and what each provides.

Kaufman Engineered Systems is a premier integrator for FANUC robotics offering robotic palletizing, depalletizing, case packing, high-speed picking, and labeling. In addition, Kaufman manufactures their own line of stretch wrapping, pallet conveying, pallet stacking, pallet dispensing, and other material handling offerings. Couple all this with in-house controls, and Kaufman has the complete solution. We'd like to help you create your next end-of-line solution.