Automated Solutions for Handling Glass Products

With over 75 years of experience, Kaufman Engineered Systems has earned our reputation as an industry leader in designing, building, and installing robotic automation systems. Our systems are scrupulously tailored to the unique needs and requirements of each customer, and when it comes to providing systems to handle delicate products such as glass, our expertise is unparalleled.

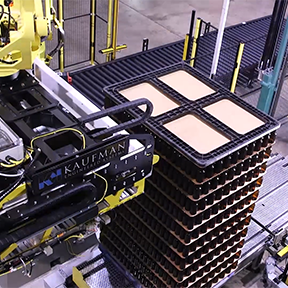

We utilize FANUC robots exclusively, along with customized end-of-arm tools we design and build in-house to ensure that systems for glass products provide the speed required while protecting the product from damage. From palletizing and depalletizing to conveying and securing, our systems integrate seamlessly into your production line, promising exceptional performance and durability.

VIEW Glass System Videos ---- Contact Us ---- Case Study ---- JOIN OUR MAILING LIST

Solving the Challenges of Packaging Glass with Robotic Systems

At Kaufman, we've had years of experience perfecting our approach to designing and constructing systems that efficiently handle glass products for customers - but our systems go beyond the palletizing/depalletizing portion of the packaging process. We incorporate additional features into these systems to ensure that the end result is dependable and consistent while preventing damage. Some of the challenges that need to be addressed with glass are as follows:

Palletizing and Depalletizing

- Fragility: Glass products are obviously extremely breakable - any mishandling during either loading or unloading pallets could lead to significant financial losses.

- Stacking: Achieving a stable stack of glass products can be difficult due to smooth and slippery surfaces and often unstable size/weight of individual products.

- Weight Distribution: Uneven weight distribution during palletization can lead to instability during any part of transport, from conveying within the system to distribution to the final destination.

Conveying

- Speed Control: Too much speed can cause breakages, while too little speed can hamper productivity by causing downtime within the production line.

- Transition Points: Glass products can easily break at transition points within the system if not handled carefully.

- Stretch wrapper to secure palletized bags for increased stability and to prevent bags from shifting during transit.

- Vibration: Excessive vibration during conveying can also lead to damage and breakage of glass.

Securing

- Material Interaction: Some materials used for securing, like certain types of straps or wraps, may interact negatively with glass, causing scratches or other damage.

- Pressure: Too much pressure during the securing process can cause the glass to crack or shatter, and too LITTLE pressure can result in unstable loads.

- Environmental Factors: Changes in temperature and humidity during storage and transportation can affect the integrity of the glass products.

Videos of Robotic Glass Palletizing/Depalletizing Systems

Key Features to Look For

When considering a robotic glass palletizing/depalletizing solution, there are several key features that businesses should look for to ensure they are choosing the right system for their needs. These include:

- Speed: The system should be capable of handling multiple products at a fast pace without compromising on safety or accuracy.

- Safety: Given the fragile nature of glass, the system must prioritize safety to minimize product damage and reduce workplace accidents.

- Speed: Precision is key in handling glass products. The system should ensure accurate placement and movement of products.

- Accuracy: Operators should be able to easily program and operate the system without extensive technical knowledge or training.

- High-Level Performance: The system should consistently deliver high-quality performance, minimizing downtime and maximizing productivity.

- Reliability: The system should have minimal downtime and require little maintenance to ensure maximum productivity.

- Cost Effectiveness: An optimal system is one that not only improves efficiency but also provides a return on investment through reduced labor costs and minimized product damage.

By selecting a robotic bag palletizing solution with these key features, businesses can improve their operations by increasing efficiency, reducing labor costs, and ensuring product quality and safety.

At Kaufman Engineered Systems, we provide top-tier automation solutions tailored to the unique needs of glass products. Our systems are designed keeping in mind the delicate nature of glass, ensuring that your products are handled with utmost care and precision.

Our automated systems are renowned for their speed, delivering quick and efficient palletizing and depalletizing while maintaining a high level of safety. We pride ourselves on our systems' accuracy, minimizing errors, and reducing the risk of product damage.

VIEW Glass System Videos ---- Contact Us ---- Case Study ---- JOIN OUR MAILING LIST