Leveraging Simulation Software to Deliver Smarter Automation Solutions

At Kaufman Engineered Systems, we don’t just build automation systems—we build confidence. Every automation solution we design, manufacture, and install is rooted in precision, performance, and a deep understanding of our customers’ unique challenges. A key part of this success? Advanced simulation software.

We harness the power of Rockwell's Emulate3D and FANUC's RoboGuide software to bring automation concepts to life before a single piece of equipment hits the production floor. These simulation tools are not just about visualization—they’re about validation, optimization, and ensuring success from concept to commissioning.

Today is the day to maximize the efficiency of your material handling needs. Contact our Automation Specialists for a free consultation. Call 419-878-9727 or email us at info@KES-USA.com.

Request a Quote ---- Contact Us ---- JOIN OUR MAILING LIST

Validating Automation Concepts with RoboGuide

When customers come to us with a new automation challenge—especially one that hasn’t been tackled before—RoboGuide is our first stop. Developed by FANUC, RoboGuide allows our R&D team to:

- Perform Reach Studies: Using detailed 2D AutoCAD layouts from our sales engineers, we import designs into RoboGuide to determine if a robot can physically reach all required points.

- Analyze Cycle Times: Whether it’s palletizing, labeling, or slip sheet placement, we simulate exact movements to ensure the solution meets strict throughput targets.

- Optimize Robot Motion: RoboGuide provides a virtual environment where robot programs can be created, tested, and refined. These programs can then be ported directly to the robot, streamlining implementation and minimizing on-site programming time.

For our engineering team, RoboGuide is a highly advanced simulation tool. It offers detailed physics, collision detection, and reach zone visualization that allows us to iron out every movement in the virtual world—long before building begins.

Designing the Full System with Emulate3D

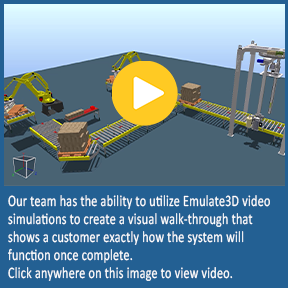

Where RoboGuide excels at motion studies, Emulate3D delivers the big picture. This dynamic simulation software is our go-to tool for designing complete automation cells. With Emulate3D, we can:

- Create Simulation: We build a full-scale, 3D model of the customer’s automation system based on their specifications.

- Show Realistic Flow: Customers can watch products move through conveyors, get wrapped, labeled, stacked, or transferred—all in a lifelike digital simulation.

- Customize Interactions: Whether it’s adjusting speeds, configuring load sizes, or showing robotic grippers in action, Emulate3D enables quick customization and real-time testing.

- Build a Modular Catalog: We continue to develop an extensive library of reusable components, such as stretch wrappers, palletizers, dual load stackers, and conveyors. These can be dragged and dropped into new designs, dramatically speeding up future project development.

Unlike RoboGuide, which focuses on the mechanics of the robot, Emulate3D gives stakeholders a visual walkthrough of how the system will function from start to finish. Think of it as a virtual tour of your automated future—ideal for customers unfamiliar with robotic systems or those needing to see the full flow before committing.

A Strategic Combination: From Concept to Confidence

The strength of Kaufman’s simulation strategy lies in how RoboGuide and Emulate3D work together:

- RoboGuide validates new concepts and ensures they meet technical and performance criteria for FANUC robots.

- Emulate3D communicates that concept clearly and compellingly to customers, stakeholders, and internal teams.

When our account managers encounter a new application, they turn to our R&D simulation specialists to determine if the concept is viable. If cycle times or reach capabilities are close to the limits, we simulate it, adjust it, and refine it. Once validated, we can use Emulate3D to present a 3D visualization to the customer, demonstrating exactly how their custom automation solution will function.

Using our simulation software allows Kaufman to eliminate guesswork, reduce design cycles, and ensure smooth transitions from concept to commissioning.

The Future: Plug-and-Play Automation

As our Emulate3D catalog grows, our ability to offer modular, customizable solutions becomes even stronger. Soon, engineers will be able to quickly configure full systems using drag-and-drop components—from conveyors to palletizers to stretch wrappers and complete automation work cells. These standardized yet customizable blocks will drastically reduce development time while maintaining the precision Kaufman is known for.

We’re also exploring advanced video rendering within Emulate3D, allowing potential customers to experience a virtual walkthrough of their system—down to the graphics on their custom boxes and pallets. This immersive tool will be a powerful aid in helping prospects visualize their ROI in real-time.

WHY IT MATTERS

Robotic automation is not a one-size-fits-all solution. It requires flexibility, foresight, and a deep understanding of each customer’s needs. Kaufman Engineered Systems is proud to lead the way by investing in cutting-edge simulation software that ensures every system we deliver performs exactly as promised.

Whether it’s proving a new concept, optimizing a complex robotic movement, or giving a first-time automation buyer confidence in their decision, simulation is the bridge between concept and reality—and at Kaufman, we’re building that bridge better than anyone else.

Request a Quote ---- Contact Us ---- JOIN OUR MAILING LIST