Belt Conveyors in Industrial Manufacturing and Distribution Processes

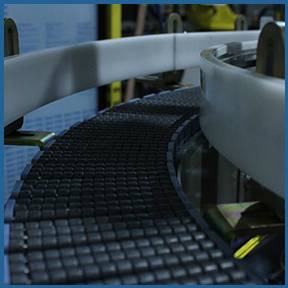

Automated system with a narrow belt sorter conveyor.

Belt conveyors are a staple in the world of industrial manufacturing, known for their efficiency in transporting materials across short and long distances. These systems play a crucial role in automating production lines, enhancing throughput, and reducing labor costs.

BASIC DESIGN & WORKING PRINCIPLES

The fundamental components of a belt conveyor system include a looped belt made from durable materials such as rubber, nylon, or PVC, which is stretched between two pulleys. One pulley, known as the drive pulley, is powered by an electric motor and moves the belt around the system; the other, often referred to as the idler pulley, guides the belt and applies tension.

TYPES OF PRODUCTS AND OPTIMAL OPERATING CONDITIONS

Belt conveyors are incredibly versatile and capable of transporting a wide variety of products, from fine powders to large, bulky items. They are especially well-suited for moving products that require gentle handling to avoid damage. Optimal operating conditions vary, but generally, these systems perform best in clean, dry environments where the risk of belt slippage is minimal.

PHYSICS & MECHANICS BEHIND BELT CONVEYORS

The principle behind belt conveyors is relatively straightforward: friction between the belt and the drive pulley allows the pulley to move the belt, which in turn moves the products along the conveyor. The amount of tension applied to the belt is critical; too little tension can cause the belt to slip, while too much can increase wear and tear on the system.

Compared to other types of conveyors, belt conveyors offer several advantages, including the ability to transport a wide range of product sizes and shapes, ease of integration into existing production lines, and relatively low operational costs. Unlike roller conveyors that rely on gravity and are best suited for uniform items, belt conveyors can move varied product types, including those that are irregularly shaped or prone to rolling.

Request Quote ---- JOIN OUR MAILING LIST ---- Contact Us

Applications in Automated Robotic Systems

24-volt motor-driven belt filled with rolling beads to create low back pressure when product accumulates.

Belt conveyors seamlessly integrate with automated robotic systems, enhancing efficiency in packaging, palletizing, securing, and depalletizing operations. These applications leverage the smooth, continuous movement of belt conveyors to feed products to robots for precise handling tasks.

- Packaging and Palletizing: In packaging applications, belt conveyors transport products to robotic packers that precisely place items into boxes or containers. For palletizing, products conveyed on belt systems are organized and stacked onto pallets by robotic palletizers. This automated process ensures accurate layering and stabilization of products for storage and shipment.

- Securing and Depalletizing: Securing processes often involve stretch wrapping machines that encase palletized goods in plastic wrap for protection during transit. Belt conveyors feed pallets into these machines and then move them onward for shipping or storage. Depalletizing, the reverse process, utilizes belt conveyors to transport goods away from robotic depalletizers, which methodically remove items from pallets for further processing or packaging.

- Integration with Other Systems: An effective automated system might combine belt conveyors with roller conveyors for varying product handling needs. For instance, delicate items can be transported on belt conveyors to a packaging station, while more robust products might transfer to roller conveyors for sorting and distribution.

Advantages and Examples

Standard belt conveyor consisting of a continuous belt that operates over rollers.

Belt conveyors offer numerous advantages, including their flexibility in handling a diverse range of products, the ability to transport items over long distances, and compatibility with automated systems. For example, in the food industry, belt conveyors transport ingredients to packaging stations where robotic arms package products quickly and accurately. In distribution centers, belt conveyors move items to palletizing robots, which stack them for shipment, demonstrating the conveyor's role in streamlining logistics processes.

In conclusion, belt conveyors serve as the backbone of many industrial manufacturing processes, offering an efficient, versatile means of material transport. When integrated with automated robotic systems, they significantly enhance productivity, accuracy, and safety in packaging, palletizing, securing, and depalletizing operations. Their adaptability makes them an indispensable tool in the creation of streamlined, automated workflows capable of handling a broad spectrum of products.

Back to List of All Conveyor Types

Request Quote ---- JOIN OUR MAILING LIST ---- Contact Us