Large Roll Handling and Mandrel Extraction in Manufacturing: The Rise of Automated Solutions

In manufacturing facilities, handling large industrial rolls and mandrels presents a considerable number of challenges. From safety risks to project timelines and high labor costs, manually managing these large and often heavy products can be a daunting task. However, the advent of automated solutions is revolutionizing the process, providing safer, more efficient, and cost-effective alternatives. This article explores the various types of automated systems available and how they can mitigate the numerous challenges tied to handling large rolls and mandrels on the production line.

The Challenges of Manual Roll and Mandrel Handling

Large industrial rolls and mandrels are cumbersome and heavy, often weighing several tons. Manually handling these items exposes workers to potential injuries from lifting or moving them. Furthermore, manual processes are time-consuming, leading to delays in project timelines.

Moreover, the manual handling of these industrial materials requires a substantial number of skilled laborers. This increases labor costs substantially and can strain the resources of a manufacturing facility.

Automated Solutions for Roll and Mandrel Handling

Several automated solutions have been developed to alleviate these issues. These include tilt tables, up-enders, horizontal and vertical stretch wrappers, weigh stations, and other state-of-the-art technologies.

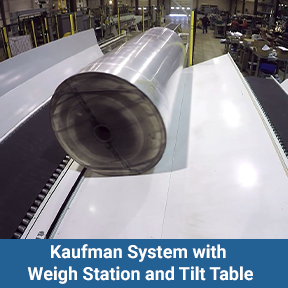

Tilt Tables: Tilt tables are designed to transfer large rolls safely from one conveyor to another. They can include a weigh station to ascertain the weight of each roll during transfer.

Up-Enders: These devices are ideal for transferring large rolls from a horizontal to a vertical position, reducing the need for manual labor and improving safety. They are particularly useful for items such as large, heavy rolls that would otherwise require significant effort and manpower to maneuver.

Horizontal and Vertical Stretch Wrappers: These machines automate the process of wrapping large rolls and mandrels, ensuring consistent, high-quality wrapping while reducing labor costs and increasing productivity.

Weigh Stations: Automated weigh stations accurately measure the weight of large rolls and mandrels, eliminating human error and increasing efficiency.

Each solution has its unique features and capabilities, and the choice depends on the specific use case. For example, an up-ender would be a beneficial investment if a manufacturing facility regularly needs to move products from a horizontal to a vertical position.

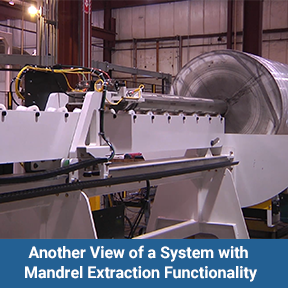

The Importance of Automated Mandrel Extraction

Mandrel extraction is a critical part of the roll-handling process. Manual extraction can damage the product or factory equipment, costing time and money for repairs. Automated mandrel extraction systems offer a solution to this problem. They ensure the safe and efficient removal of mandrels, protecting both the product and the equipment from potential harm.

Automated mandrel extraction systems usually feature advanced sensors and precision controls to achieve smooth and efficient operation. These features reduce the risk of damage and enhance overall productivity.

In conclusion, automated solutions for large roll handling and mandrel extraction are transforming manufacturing operations. They increase safety, improve efficiency, and reduce labor costs, making them a valuable investment for any manufacturing facility dealing with large industrial rolls and mandrels. Manufacturers can select the most appropriate and beneficial automated systems for their operations by carefully evaluating their specific needs and available options.

Kaufman Engineered Systems: Pioneering Automated Solutions for Large Roll Handling and Mandrel Extraction

Kaufman Engineered Systems, a renowned name in the world of industrial automation, has been at the forefront of designing, building, and integrating automated solutions for a wide range of manufacturing applications, including large roll handling and mandrel extraction, for over 75 years. Kaufman Engineered Systems is an industry leader with a reputation built on experience, innovation, and customer satisfaction, setting the standard for high-quality, efficient, and customizable solutions.

No two manufacturing facilities are alike, and Kaufman Engineered Systems understands this. The company excels at developing custom solutions based on each customer's unique needs and applications. This tailored approach ensures that every solution is optimized for maximum efficiency and performance.

Comprehensive Support and Services

Beyond their innovative solutions, Kaufman Engineered Systems also offers comprehensive support and services. They provide full installation assistance, ensuring that the integration of completed systems into your facility is smooth and hassle-free.

In addition, Kaufman offers training resources to help your team understand and operate the new systems effectively. They also provide ongoing maintenance and support to ensure that their solutions continue to deliver optimal performance over time.

In conclusion, Kaufman Engineered Systems' expertise in designing and integrating automated solutions for large roll handling and mandrel extraction is unparalleled. Their customized approach and commitment to customer satisfaction make them a trusted partner for any manufacturing facility looking to enhance efficiency and performance.

JOIN OUR MAILING LIST ---- Contact Us ---- Request Quote

Large Roll Handling and Mandrel Extraction Videos

Kaufman Engineered Systems is a premier integrator for FANUC robotics offering robotic palletizing, depalletizing, case packing, high-speed picking, and labeling. In addition, Kaufman manufactures their own line of stretch wrapping, pallet conveying, pallet stacking, pallet dispensing, and other material handling offerings. Couple all this with in-house controls, and Kaufman has the complete solution. We'd like to help you create your next end-of-line solution!

JOIN OUR MAILING LIST ---- Contact Us ---- Request Quote