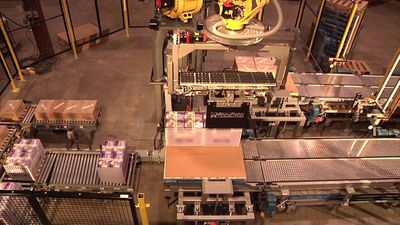

Kaufman Robotic Tray Palletizing System Integrating FANUC Robotics

Robotic Picking Container Products:

A variety of FANUC robots can be considered for picking applications. Typically low weight and high speed are the criteria for picking applications. FANUC’s line of Delta Robots (M-1iA Series, M-2iA Series, M-3iA Series, DR-3iB Series) and FANUC’s new line of SCARA SR-iA Series of robots are popular due to their high speed and precise performance. Kaufman Engineered Systems will qualify your requirements and apply the model robot, safety, and controls to achieve the optimum solution. From plastic and glass containers, have KES help create your new high speed picking solution.

Automated Packing of Container Products:

Robotic packing solutions usually means low to medium weight ranges and handling a variety of packages or products. Plastic laundry jugs, beverage bottles, glass food jars, steel cans, and other PET containers are common products in this space. They may be packed in a variety of formats and packaging including trays along with case, bundle, or film overwrap bundles. Kaufman will qualify, test, design, manufacture and install the complete packing solution.

Contact Us ---- JOIN OUR MAILING LIST ---- Request Quote

Standard Features:

- Allen Bradley control components

- Kaufman Engineered Systems manufactured end-of-arm tooling

- Category (3) safety architecture

Additional Options:

- Slip sheet capability

- Tier sheet capability

- Pallet pick or automatic feed

- Transfer-unit mounted robots for moving between feed and build lanes and accommodating multiple stack locations

- Integrated vision

- Infeed product conveyor

- Discharge full unit conveyor and handling equipment

- UL 508A listed control panel

- CUL control panel

- Robotic system installation services >

Calculate the benefits when you automate with Kaufman Engineered Systems Robotic Palletizing Solutions:

- Increased line efficiency

- Increased production

- Improved quality of finished units

- Greater line flexibility

- Reduction in labor injuries

- Reduction in staffing requirements

As an Authorized Systems Integrator for Fanuc Robotics, Kaufman Engineered Systems applies Fanuc robot technology to provide customers complete end of line system solutions.

The solution may be as simple as a dedicated palletizing cell, or as complex as a multi-line handling and palletizing system. No matter how big or small, Kaufman Engineered Systems will address each project and customer with the same integrity and professional response.

The K5 group is available in many models, including:

Kaufman Engineered Systems is a premier integrator for FANUC robotics, offering robotic palletizing, depalletizing, case packing, high-speed picking, and labeling. In addition, Kaufman manufactures their own line of stretch wrapping, pallet conveying, pallet stacking, pallet dispensing, and other material handling offerings. Couple all this with in-house controls, and Kaufman has the complete solution. Let us help you create your next end-of-line solution.

Why Companies Choose Kaufman Engineered Systems?

- Stability: With over 75 years of serving our customers, Kaufman continues to provide innovative products backed by five-star service.

- Quality: No one can match our machinery’s superior construction and durability.

- Dependability: With our 24-hour service support, you can count on Kaufman to be there when you need us most.

- In House Design and Manufacturing: Kaufman employs a full staff of electrical, mechanical, and robotic engineers to design and install the machines that meet your specific needs.

- Commitment to Excellence: We are customer-focused, and we recognize that there are no universal automation solutions. Your needs are thoroughly analyzed and reviewed by our engineering staff to find the most efficient, cost-effective solution for your business.

- Your Turn-Key Provider: From machine fabrication to installation and start-up, Kaufman is there to support you.

- Improve your Bottom-Line: Whether it’s shaving seconds off cycle time or squeezing space out of your plant layout, we are committed to improving your efficiencies and operating costs.

Contact Us ---- JOIN OUR MAILING LIST ---- Request Quote