Roller Conveyors in Industrial Manufacturing and Distribution Processes

24-volt motor-driven roller conveyor with bi-directional pop-up transfer feature for sorting.

Roller conveyors are a fundamental component in automating manufacturing and distribution processes. They are known for their simplicity, efficiency, and reliability. They play a pivotal role in moving goods through various stages of production and logistics operations.

BASIC DESIGN AND WORKING PRINCIPLES

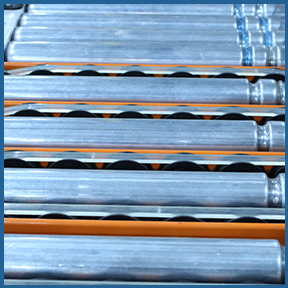

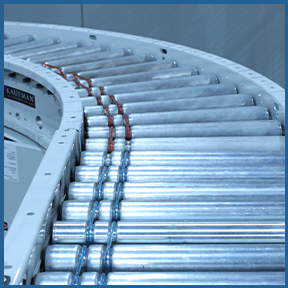

The design of roller conveyors consists of multiple rollers mounted in a frame, which can be powered (driven) or unpowered (gravity). Powered roller conveyors use motors to turn the rollers, propelling items along the conveyor path. On the other hand, gravity roller conveyors rely on a slight decline in elevation, allowing goods to move under the force of gravity.

TYPES OF PRODUCTS & OPTIMAL OPERATING CONDITIONS

Roller conveyors are adept at handling a wide array of product types, particularly items with rigid, flat bottoms, such as boxes, pallets, and trays. They are most effective in controlled environments where the risk of debris interfering with the rollers is minimized. Optimal operating conditions also include applications where products need to be moved smoothly with minimal friction and resistance.

PHYSICS & MECHANICS BEHIND ROLLER CONVEYORS

The operation of roller conveyors is governed by the principles of mechanics and physics, specifically Newton's First Law of Motion: an object in motion stays in motion with the same speed and in the same direction unless acted upon by an unbalanced force. In powered systems, the motor applies a force to turn the rollers. In gravity systems, the gravitational pull provides this force. The spacing of rollers is critical; too far apart and products can sag or become stuck, too close together and the system's efficiency decreases.

Compared to other types of conveyors, roller conveyors are particularly efficient for transporting heavy loads over short to medium distances. Unlike belt conveyors that apply a continuous surface for movement, roller conveyors provide point-to-point contact, reducing friction and facilitating easier handling of large, heavy items.

Request Quote ---- JOIN OUR MAILING LIST ---- Contact Us

Applications in Automated Robotic Systems

Belt conveyors seamlessly integrate with automated robotic systems, enhancing efficiency in packaging, palletizing, securing, and depalletizing operations. These applications leverage the smooth, continuous movement of belt conveyors to feed products to robots for precise handling tasks.

Packaging and Palletizing: In packaging applications, belt conveyors transport products to robotic packers that precisely place items into boxes or containers. For palletizing, products conveyed on belt systems are organized and stacked onto pallets by robotic palletizers. This automated process ensures accurate layering and stabilization of products for storage and shipment.

Securing and Depalletizing: Securing processes often involve stretch wrapping machines that encase palletized goods in plastic wrap for protection during transit. Belt conveyors feed pallets into these machines and then move them onward for shipping or storage. Depalletizing, the reverse process, utilizes belt conveyors to transport goods away from robotic depalletizers, which methodically remove items from pallets for further processing or packaging.

INTEGRATION WITH OTHER CONVEYOR TYPES

An effective automated system might combine belt conveyors with roller conveyors for varying product handling needs. For instance, delicate items can be transported on belt conveyors to a packaging station, while more robust products might transfer to roller conveyors for sorting and distribution.

Advantages and Examples

Roller conveyors offer numerous advantages, including modularity, durability, and ease of maintenance. Their ability to handle products of various sizes and shapes, combined with high reliability, makes them a preferred choice in many industries.

For example, in the e-commerce sector, fulfillment centers utilize roller conveyors extensively. Packages are transported from storage areas to packaging stations, where they are prepared for shipment. In automotive manufacturing, components are moved along assembly lines on roller conveyors, where robots perform tasks like welding and assembly.

In conclusion, roller conveyors are indispensable in industrial manufacturing processes, providing efficient, reliable transport of goods across various stages of production and distribution. Their integration with automated robotic systems further enhances operational efficiency, offering a streamlined approach to handling a diverse range of products. Through thoughtful implementation, roller conveyors can significantly contribute to the effectiveness and efficiency of automated systems.

Back to List of All Conveyor Types

Request Quote ---- JOIN OUR MAILING LIST ---- Contact Us