Skatewheel Conveyors in Industrial Manufacturing and Distribution Processes

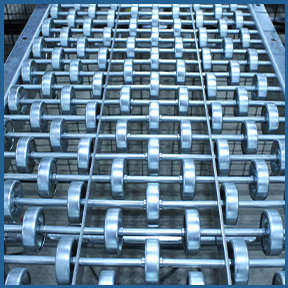

Skatewheel Gravity Conveyor

Skatewheel conveyors, a subtype of the broader category of roller conveyors, are an essential component in the efficient movement of goods within industrial manufacturing and distribution environments. Their unique design and operational mechanics make them particularly suited for specific applications across various industries.

BASIC DESIGN & WORKING PRINCIPLES

Skatewheel conveyors consist of a series of small wheels, or "skatewheels," mounted on axles and arranged in tracks. These wheels can be made of steel, aluminum, or plastic, each offering different durability and cost benefits. The skatewheels roll independently, allowing for smooth and easy movement of items along the conveyor.

Unlike traditional roller conveyors that have larger cylinders, the smaller size and greater number of skatewheels provide more contact points with the cargo. This design facilitates the transportation of items with uneven bottoms or those that are too small to span the gap between rollers on a conventional roller conveyor.

TYPES OF PRODUCTS & OPTIMAL OPERATING CONDITIONS

Skatewheel conveyors are ideal for moving lightweight to medium-weight items with rigid bottoms. They are particularly effective in operations where goods need to be diverted or converged along the transport path due to the ease with which items glide over skatewheels. Optimal operating conditions include dry environments with relatively clean floors, as debris can hinder the motion of the wheels.

Request Quote ---- JOIN OUR MAILING LIST ---- Contact Us

In-Depth Information About Skatewheel Conveyors

An example of a system that integrates both a 24-volt motor-driven roller conveyor and a skatewheel gravity conveyor.

PHYSICS & MECHANICS BEHIND SLAT CONVEYORS

The physics behind skatewheel conveyors involves principles of rolling resistance and load distribution. Each skatewheel acts independently to support a portion of the load's weight, distributing it evenly across multiple points. This distribution minimizes friction and makes it easier to move loads with minimal effort. Compared to belt conveyors, skatewheel systems offer less resistance and require less power to move items, especially in manual (gravity-fed) configurations. However, they may not be as suitable for very heavy or large items that could benefit from the continuous support a belt provides.

APPLICATIONS IN AUTOMATED ROBOTIC SYSTEMS

Skatewheel conveyors integrate well with automated robotic systems in several key manufacturing and distribution processes:

- Packaging: In packaging lines, skatewheel conveyors transport individual items to workstations where robotic arms package them. Their smooth operation allows for precise positioning required for automated packaging equipment.

- Palletizing and Depalletizing: For palletizing, products move along skatewheel conveyors to robotic palletizers that stack goods on pallets in a pre-determined arrangement. The reverse process, depalletizing, also benefits from the flexibility and ease of item transfer skatewheel conveyors provide.

- Securing and Labeling: Automated systems that wrap or secure products for shipping can receive goods efficiently via skatewheel conveyors. Similarly, labeling machines benefit from the steady flow of products that these conveyors deliver, ensuring accurate label placement.

INTEGRATING WITH OTHER CONVEYOR TYPES

Creating an effective and efficient automated system often involves pairing skatewheel conveyors with other types of conveyors. For example, belt conveyors might handle the initial stages of a production line, moving delicate items that require a stable base. Those items could then transition onto skatewheel conveyors for sorting and distribution processes where their lightweight nature and speed are advantageous. Similarly, heavier items could be transferred from chain conveyors onto skatewheel conveyors for final packaging and labeling.

Advantages of Skatewheel Conveyors

Example of integrating motor-driven mattop with skatewheels for low back pressure in areas of accumulation.

One of the main advantages of skatewheel conveyors is their flexibility. They can be easily configured into curved paths, diverging or converging lines, making them ideal for facilities with limited space. Additionally, their modular design allows for quick setup and reconfiguration according to changing production needs.

An illustrative example would be in e-commerce fulfillment centers, where diverse products must be quickly sorted and directed to specific packing areas. Here, skatewheel conveyors can swiftly move items from storage bins to packing stations, where they are prepared for shipment. Another example is in postal sorting facilities, where mail packages of varying sizes and weights are sorted and routed to different processing areas with the help of skatewheel conveyors.

In conclusion, skatewheel conveyors offer a versatile and efficient solution for moving goods in industrial manufacturing processes, particularly where speed, flexibility, and adaptability are crucial. Their integration into automated systems enhances productivity and operational efficiency, showcasing their indispensable role in modern industrial operations.

Back to List of All Conveyor Types

Request Quote ---- JOIN OUR MAILING LIST ---- Contact Us