Slat Conveyors in Industrial Manufacturing and Distribution Processes

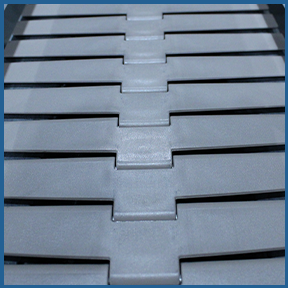

Standard slat conveyor to move products through production line.

Slat conveyors are a fundamental element in industrial manufacturing, offering a robust and versatile method for transporting goods across various stages of production and distribution. Their unique design and operational principles make them suited to a broad array of applications, extending from heavy-duty material handling to precise product positioning in conjunction with automated systems.

BASIC DESIGN & WORKING PRINCIPLES

Slat conveyors consist of a series of slats—flat, rigid plates or planks made of metal, wood, or plastic—attached to a chain. This chain loops around sprockets at each end of the conveyor frame, driven by a motor, which propels the slats in a continuous loop. The slats themselves provide a solid, flat surface for products to rest on as they are transported.

TYPES OF PRODUCTS & OPTIMAL OPERATING CONDITIONS

Slat conveyors are incredibly adaptable and capable of transporting a wide range of products, including heavy, bulky items or delicate goods that require a stable base during movement. They are particularly useful for items that are too large or awkwardly shaped for belt conveyors or that might be damaged by the rollers of a roller conveyor system. Optimal operating conditions for slat conveyors are those that require the transport of goods over long distances within manufacturing plants, under extreme temperatures, or in environments where cleanliness and hygiene are paramount.

Request Quote ---- JOIN OUR MAILING LIST ---- Contact Us

In-Depth Information About Slat Conveyors

Closeup of standard slat conveyor.

PHYSICS & MECHANICS BEHIND SLAT CONVEYORS

The mechanics of slat conveyors involve the transfer of power from the motor to the sprockets, which in turn move the chain and attached slats along the conveyor frame. This direct drive system provides efficient power transmission and precise control over the movement of the slats, allowing for the smooth transportation of goods.

Compared to other types of conveyors, slat conveyors offer notable advantages in terms of load capacity and stability. Unlike belt conveyors, which can sag under heavy loads, the rigid nature of slats ensures that products remain level and secure. Similarly, while roller conveyors rely on gravity and may not guarantee alignment, slat conveyors keep items in precise positions throughout their journey.

APPLICATIONS IN AUTOMATED ROBOTIC SYSTEMS

Slat conveyors integrate seamlessly into automated manufacturing and distribution processes thanks to their stability and versatility. They are particularly effective in applications such as:

- Packaging: Where products need to be transported to different stations for wrapping, boxing, or sealing.

- Palletizing: Where robotic systems stack products on pallets for shipping, the stable platform of a slat conveyor ensures accurate placement.

- Securing: In operations where products must be held firmly in place for processes like labeling or assembly.

- Depalletizing: Where goods are removed from pallets for further processing or packaging.

PAIRING WITH OTHER CONVEYOR TYPES

For maximum efficiency, slat conveyors can be paired with other types of conveyors to handle a wider range of products and tasks. For instance, belt conveyors can transport lighter items or raw materials to a slat conveyor system, where heavier or more delicate products are precisely positioned for robotic packaging. Similarly, vertical lift conveyors could feed items onto slat conveyors for horizontal transport through automated assembly lines.

Advantages of Slat Conveyors

Slat conveyors offer several key advantages, including durability, stability, and ease of maintenance. Their ability to operate in harsh environments—such as high temperatures or wet conditions—makes them indispensable in sectors like food and beverage processing, pharmaceuticals, and heavy manufacturing.

In conclusion, slat conveyors are a critical component of modern industrial manufacturing processes, providing a reliable and versatile solution for transporting a wide variety of products. Their integration into automated systems enhances efficiency and productivity, making them a staple in facilities aiming for operational excellence.

Back to List of All Conveyor Types

Request Quote ---- JOIN OUR MAILING LIST ---- Contact Us